Custom Precision Metals

Meet your custom precision metals needs by leveraging Laird’s end-to-end engineering expertise and flexibility, accurate forecasting of issues, off-the-shelf solutions, and quick turnaround.

Explore Laird’s vast array of custom precision metals products with counterbore-like features – from fingerstock gaskets to board-level shielding solutions to SMD grounding contacts. These custom solutions are thinner and lighter, helping you save space, and many ensure zero air gap. It’s our industry-leading quality, on-time performance and renowned engineering prowess that deliver the difference. We invite you to examine our quality certificates, then compare, save on TCO, and succeed.

● Hundreds of standard parts

● Rapid modifications produce custom designs

● Automated 100 percent coplanarity inspection system

● Innovative experts creating small, compact designs

● Resolve multiple issues by integrating metals with thermal/absorber materials

● PTC Creo, AutoCAD, Solidworks

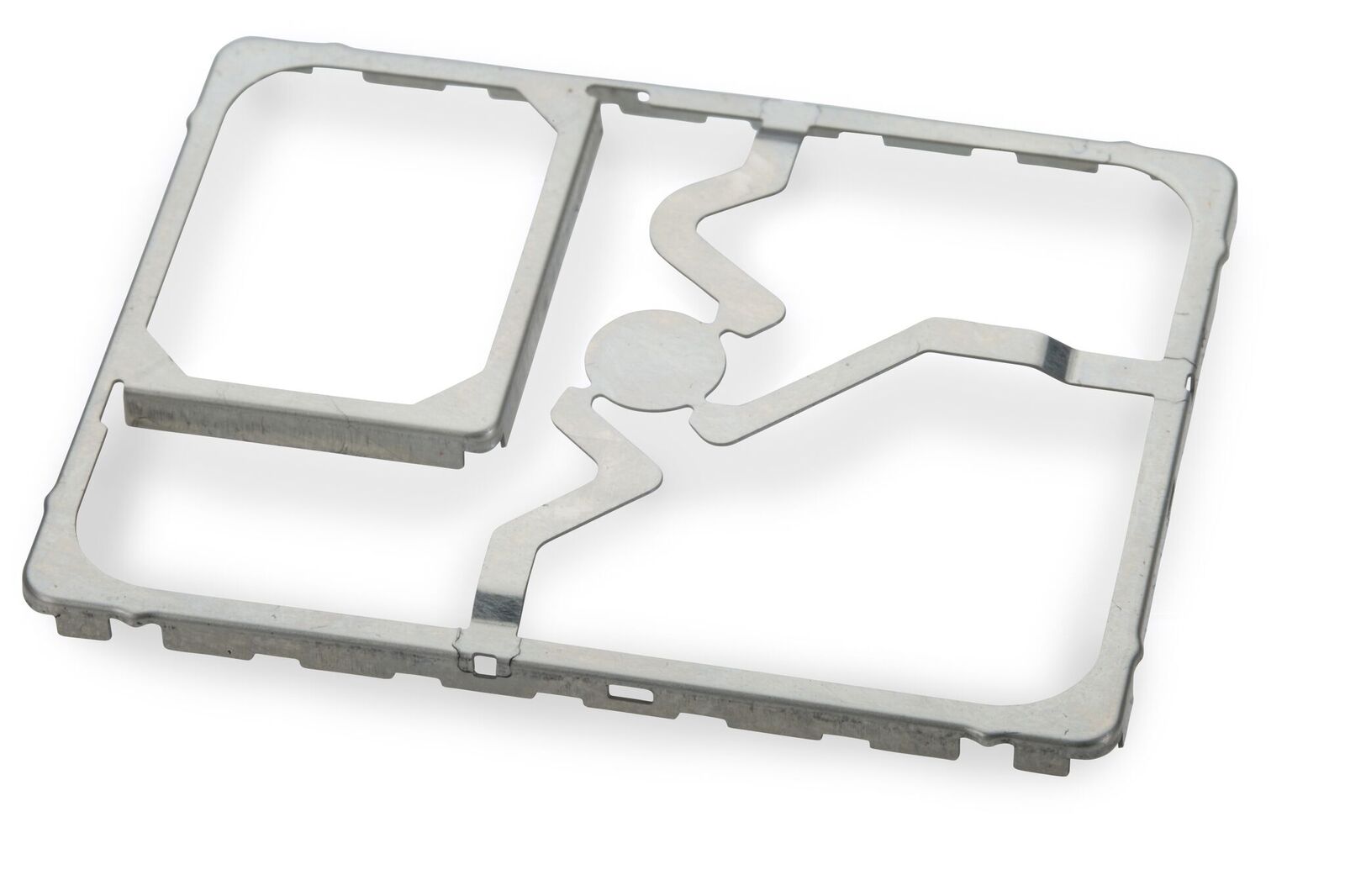

Board-Level Shielding

Laird is a global leader in board-level shielding which effectively blocks unwanted waste energy for surface mount applications in countless devices.

Whether it is a one-piece shield, a multi-compartmental or deep draw shield or precision contact, Laird quickly designs and delivers best-value products offering maximum performance. Advanced laser welding and adhesive metal-joining technologies are just two recent innovations that enhance Laird’s board-level shielding solutions.

Laird’s expertise ensures that parts perform in superior fashion while optimizing your application. We use the latest systems to develop part designs in just hours.

● Many standard board-level shields meet several off-the-shelf application requirements

● Most shields can be modified for your custom design

● Our shields are thinner, lighter, save space and enable zero air gap

● Coplanarity of 0.05 mm (depending on part size) allows less use of solder

● Automated 100% coplanarity inspection system

● In-line production process includes part formation, cleaning, assembly, inspection and automated packaging

● Laird ingenuity has produced design features such as rigid corners, removable pick bridges (where replaceable covers enable repairs), and ultra-low height (<1.0 mm) shields

● Our vertical integration capabilities combine precision metals with a dielectric insulation coating, a thermal interface material, and/or an absorber material, providing you with a complete solution in a single process design

Learn more about board-level shielding

Fingerstock Gaskets

Laird’s engineered metal fingerstock gasket solutions date back to 1938. We specialize in designing miniature thin strip metal parts in quantities ranging from thousands to millions of pieces. With nearly 4,000 standard parts, we likely have an off-the-shelf solution to meet your needs.

If a custom fingerstock gasket design is required, Laird’s engineering team works to maximize efficiencies in performance, cost and manufacturability from the beginning stages of an application.

● Many standard fingerstock parts meet off-the-shelf application requirements

● Standard fingerstock parts can be modified for your custom design

● We use advanced simulation capabilities to accurately identify potential design issues

● See our specialized fingerstock capabilities from design through manufacturing

Laird solves any fingerstock need:

High precision assembly

Heat staking (both hand and automatic)

Heat treating

In-house die and fixture manufacturing

Multislide equipment

Photoetching

Plating

Progressing die stamping

Prototype fabrication

Resistance welding

Riveting

Secondary fabrication

Wire EDM

SMD Grounding Contacts

Laird’s standard precision electronic contacts deliver complete solutions. Our contacts will ground, carry current and signals, and interconnect boards and devices. A wide variety of plating options enables maximum electrical current-carrying performance.

You achieve optimal performance even while resolving EMI in extremely small, complex devices. What else is important? Installed costs of Laird grounding contacts are lower with our tape and reel packaging.

● Many standard grounding contacts meet off the shelf application requirements

● Standard SMD grounding contacts can be modified for your custom design

● Look to us for custom grounding or battery contacts and mechanical springs

● See our wide variety of plating options and array of standard format designs

● Our SMD grounding contacts satisfy each of your functional, assembly and packaging requirements